-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

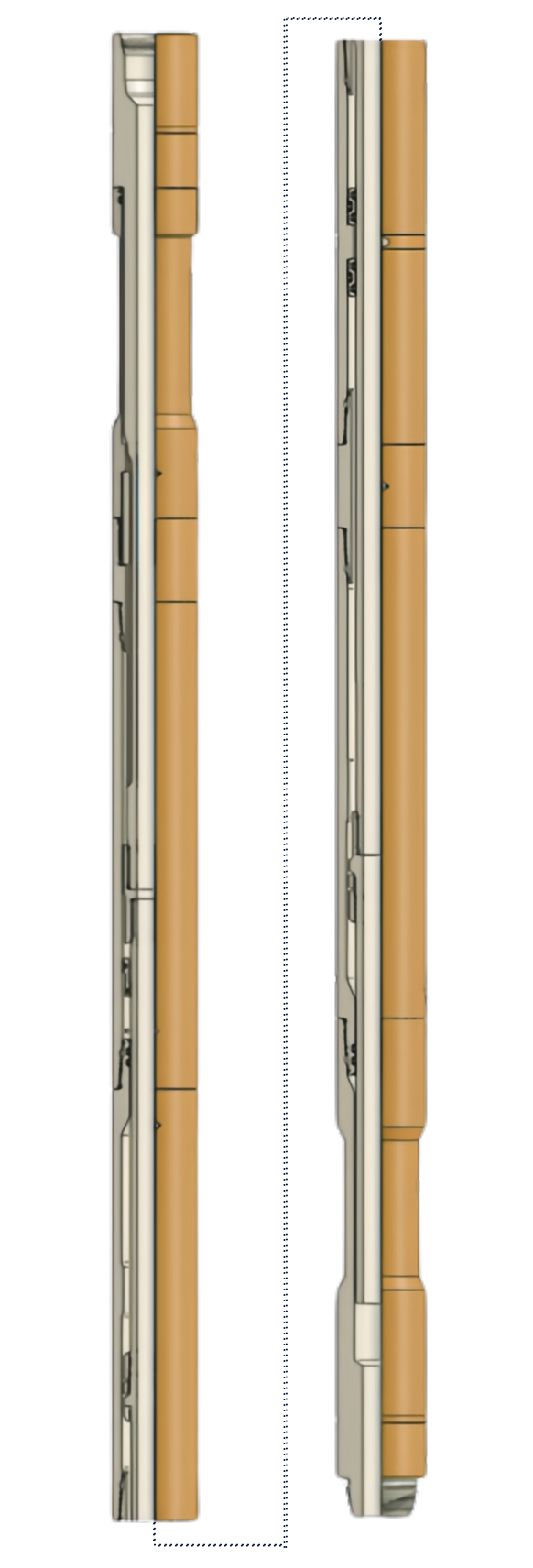

HYDRAULIC DRILLING JAR

TECHNICAL SUMMARY

Hydraulic jar is one of the drilling jars types used in drilling operations to free stuck pipe problem.

Orchid Energy hydraulic drilling jar will allow the operator to apply variable impact in both the up and down directions. It can protect the drill string effectively and improve the using life. The hydraulic stored energy mechanism has the advantage of reliable property and good stability. The scope of time delay interval can be 30s~240s; the scope of service temperature can be -40℃~180℃. It can adopt the new special material for higher property and safety. It can normally used for drilling, coring, work over and fishing etc.

SPECIFICATION

|

Model |

QYZ121 |

QYZ165 |

QYZ203 |

QYZ241 |

|

OD mm(inch) |

121(4 3/4) |

165(6 1/2) |

203(8) |

241(9 1/2) |

|

ID mm(inch) |

44.5(1 3/4) |

57.2(2 1/4) |

70(2 3/4) |

76.2(3) |

|

Tool Joint Conn. API |

NC38 |

NC50 |

6 5/8REG |

7 5/8REG |

|

Max.Upward Jarring Force KN(lbf) |

350(79,000) |

700(160,000) |

1000(235,000) |

1250(280,000) |

|

Max.Downward Jarring Force KN(lbf) |

180(40,000) |

350(79,000) |

500(112,000) |

650(140,000) |

|

Max. Tensile Load KN(lbf) |

1100(247,000) |

2000(450,000) |

2800(630,000) |

3500(780,000) |

|

Tensile Yield KN(lbf) |

1950(438,000) |

3750(843,000) |

6650(1,495,000) |

9850(2,210,000) |

|

Torsional Limited KN·m(lbf·ft) |

15(11,000) |

30(22,000) |

45(33,000) |

75(56,000) |

|

Torsional Yield KN·m(lbf·ft) |

27(20,000) |

75(55,000) |

90(66,000) |

150(112,000) |

|

OAL mm(ft) |

6063(19.9) |

6375(20.9) |

6692(22) |

6920(22.7) |

FEATURES

2. The unique sealing structure design not only improves temperature resistance but also enhances sealing reliability.

3. The core structure adopts a sealed oil bath design to reduce wear on moving parts and improve the overall lifespan of the machine.

4. Increase the discharge channel's overcurrent area, reduce operational resistance, and significantly improve the shock effect.

5. The operating force of the hydraulic release mechanism is controllable on the ground, and the driller can flexibly adjust it according to the underground situation.

HYDRAULIC DRILLING JAR

ORCHID ENERGY CO., LTD. COPYRIGHT 2024©️

GENERAL LINKS