-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

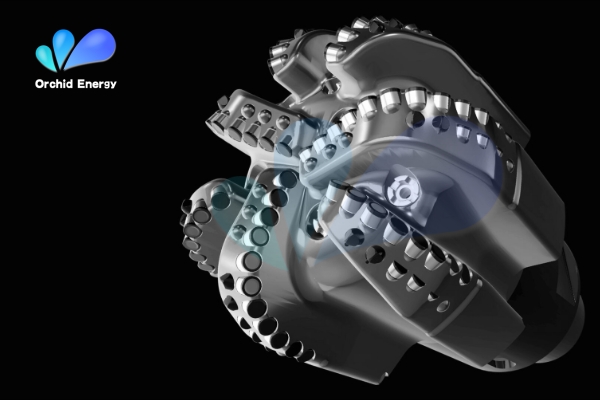

Enhancing Drilling Efficiency: The Power of PDC Drill Bits

PDC drill bits have gained immense popularity due to their exceptional durability, efficient cutting capabilities, and ability to handle various drilling conditions. This blog will delve into the mechanics, benefits, and applications of PDC drill bits in the oil and gas industry.

1. The Mechanics behind PDC Drill Bits:

PDC drill bits are equipped with small synthetic diamond cutters, or "compact" elements, which are made by combining diamond grit and a catalyzing agent under high pressure and temperature. These cutters are arranged on the bit in a matrix or a layered pattern, enabling the bit to effectively penetrate rock formations. This unique design allows PDC drill bits to deliver superior performance compared to traditional roller cone drill bits.

2. Advantages of PDC Drill Bits:

2.1 Exceptional Durability and Wear Resistance:

One of the standout features of PDC drill bits is their remarkable durability. The diamond cutters used in PDC bits possess excellent wear resistance, enabling them to withstand extremely harsh drilling environments. This durability translates into increased bit longevity, reducing the downtime and costs associated with frequent bit changes.

2.2 Efficient Cutting Capabilities:

PDC drill bits are highly efficient in cutting through various formations, including soft formations, hard formations, and abrasive formations. The diamond cutters on PDC bits have sharp edges that can continuously grind through rock, ensuring rapid and efficient penetration. This efficiency leads to faster drilling rates, ultimately saving valuable time and resources.

2.3 Enhanced Stability and Steerability:

PDC drill bits offer improved stability and steerability during drilling operations. With their compact design, these bits generate minimal vibrations while drilling, resulting in reduced friction and enhanced control. This stability allows for smoother drilling operations, reducing the risks of bit damage and increasing overall drilling accuracy.

3. Applications of PDC Drill Bits:

3.1 Oil and Gas Exploration:

PDC drill bits have become a staple in the oil and gas industry for their excellent performance in both conventional and unconventional drilling operations. Whether drilling vertical or horizontal wells, PDC bits deliver reliable and consistent results, ensuring efficient extraction of hydrocarbon resources.

3.2 Geothermal Drilling:

PDC drill bits are also extensively used in geothermal drilling projects. The ability of PDC bits to handle challenging formations and maintain their cutting efficiency for extended periods makes them ideal for drilling deep geothermal wells, where temperatures and rock hardness can vary significantly.

3.3 Mining and Construction:

Beyond the energy sector, PDC drill bits find applications in mining and construction projects. These bits are highly effective in excavating tunnels, blasting through hard rock, and creating boreholes for various purposes. The versatility of PDC bits makes them a preferred choice for demanding mining and construction applications.

Conclusion:

PDC drill bits have undoubtedly revolutionized drilling operations in the oil and gas industry and beyond. Their exceptional durability, efficient cutting capabilities, and versatility have transformed the way we explore and exploit natural resources. With ongoing advancements and innovations, PDC drill bits continue to push the boundaries of drilling efficiency, enabling safer, faster, and more cost-effective operations in various sectors.