-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

Safeguarding Drilling Operations: Best Practices for Drill Rig Safety

1. Prioritizing Drill Rig Safety:

1.1 Rigorous Safety Training:

Training is the backbone of drill rig safety. Ensuring that all personnel receive comprehensive safety training specific to their roles is crucial. This includes training on hazard identification, emergency response procedures, proper use of personal protective equipment (PPE), and safe operation of drilling tools and equipment.

1.2 Regulatory Compliance:

Adhering to industry regulations and local safety standards is imperative. Regulatory agencies often provide guidelines for drilling operations to minimize risks and ensure uniform safety practices. Rig managers must stay updated on regulations and ensure compliance throughout their operations.

2. Key Drilling Tools for Enhanced Safety:

2.1 Blowout Preventer (BOP):

The BOP is a critical safety device that prevents uncontrollable releases of pressure during drilling operations. It consists of a series of valves that seal the wellbore, preventing the uncontrolled release of hydrocarbons. Regular maintenance, testing, and proper functioning of the BOP are vital for drilling safety.

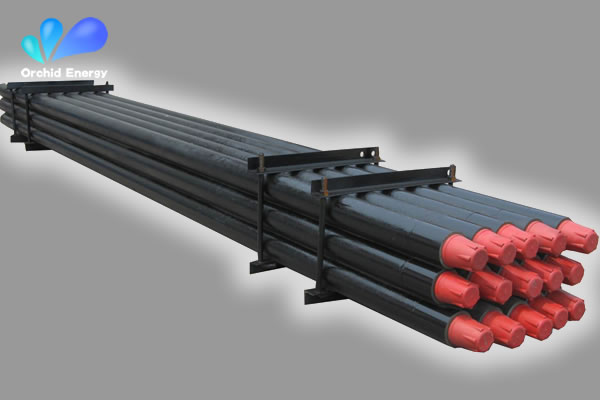

2.2 Drill Pipe:

Drill pipes connect the drilling rig on the surface to the drill bit downhole. Ensuring the integrity and strength of drill pipes is essential to prevent accidents such as pipe failures, stuck pipes, or loss of circulation. Regular inspection and maintenance, including non-destructive testing, are crucial to mitigate risks.

2.3 Safety Valves:

Safety valves provide an additional layer of protection by shutting off the flow of fluids in the event of pressure fluctuations or a sudden surge. These valves are designed to maintain well control and prevent blowouts. Regular testing and maintenance of safety valves contribute to overall drilling safety.

3. Best Practices for Drill Rig Safety:

3.1 Risk Assessment and Management:

Conducting comprehensive risk assessments before commencing drilling operations helps identify potential hazards and develop appropriate mitigation strategies. Regular monitoring and reassessment of risks throughout the drilling process ensure ongoing safety.

3.2 Effective Communication and Emergency Response:

Establishing clear communication protocols among team members, including the use of radio systems and safety meetings, is crucial. Training drills, safety briefings, and well-defined emergency response plans help ensure rapid and effective responses in case of emergencies.

3.3 Preventive Maintenance and Inspection:

Regular preventive maintenance of drilling equipment, including drilling tools, ensures their proper functioning and reduces the risk of equipment failure. Routine inspections should be conducted to identify and address any potential issues proactively.

Conclusion:

Drill rig safety must be a top priority in any drilling operation. By proactively implementing best practices, adhering to regulations, and leveraging key drilling tools, companies can minimize risks, protect personnel, and promote a culture of safety. Regular training, effective communication, and participation in industry safety initiatives contribute to the continuous improvement of drilling safety. Upholding high standards of safety not only ensures the success of drilling operations but also safeguards the well-being of all involved and protects the environment.

Tags: Drill Pipe | Float Valve | Lifting Sub