-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

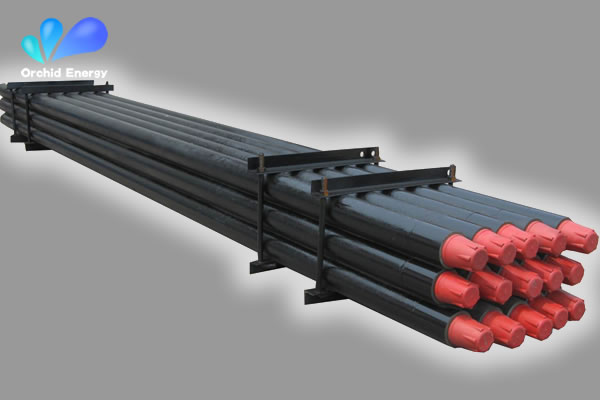

Drill Pipe Explore Article 1 - Standard Drill Pipe

Introduction:

Standard drill pipes are essential components in drilling operations, connecting the drill bit with the surface drilling equipment. This blog explores the materials used, key production processes, application scenarios, international inspection standards, maintenance considerations, and real application cases of standard drill pipes. Additionally, relevant parameters will be summarized in tables for better understanding.

1. Materials Used in Standard Drill Pipes:

Standard drill pipes are typically made from high-quality alloy steel, providing the necessary strength and durability for drilling operations. Commonly used steel grades include:

1.1 API Grade E75:

API Grade E75 drill pipes are manufactured from medium carbon steel and offer excellent mechanical properties, including high tensile strength and impact resistance.

1.2 API Grade X95:

API Grade X95 drill pipes are manufactured from higher strength alloy steel, providing enhanced performance in demanding drilling conditions and deeper wells.

2. Key Production Processes:

2.1 Pipe Cutting and Heating:

Steel tubes are cut to the required length and then heated to a high temperature to improve their plasticity and facilitate subsequent processing.

2.2 Upsetting:

The ends of the tubes are heated and forged to increase their outer diameter, ensuring proper connection strength and preventing leaks.

2.3 Threading:

The pipe ends are threaded using specialized machinery, creating precise connections that allow for easy assembly and disassembly during drilling operations.

2.4 Heat Treatment:

Drill pipes undergo heat treatment processes such as annealing or tempering to enhance their mechanical properties, making them more durable and resistant to wear and fatigue.

3. Application Scenarios:

Standard drill pipes are utilized in various drilling applications, including:

3.1 Oil and Gas Exploration:

Standard drill pipes are extensively used in oil and gas exploration, enabling the drilling of vertical, directional, and horizontal wells to access hydrocarbon reservoirs.

3.2 Geothermal Drilling:

Drill pipes are employed in geothermal drilling to extract heat from the earth, contributing to renewable energy production.

3.3 Construction and Mining:

Drill pipes are essential in construction and mining operations, enabling the drilling of foundation piles, water wells, and mineral extraction.

4. International Inspection Standards:

To ensure the quality and reliability of standard drill pipes, industry-wide product inspection standards are followed, including:

4.1 API Spec 7:

API Spec 7 provides detailed specifications for drill pipe manufacturing, covering dimensional requirements, mechanical properties, chemical composition, inspection procedures, and testing methods.

4.2 ISO 11961:

ISO 11961 is an international standard that specifies requirements and gives recommendations for drill stem design and operating practices based on API standards.

5. Maintenance and Precautions:

Proper maintenance and precautions are crucial for the safe and effective use of standard drill pipes. Consider the following:

5.1 Precautions During Use:

- Inspect drill pipes regularly for signs of wear, corrosion, or damage.

- Avoid exceeding the recommended drilling parameters, including weight on bit and torque limitations.

- Use appropriate drilling fluids and lubricants to reduce friction and heat generation during drilling.

5.2 Maintenance Methods:

- Clean and inspect drill pipes after each use to remove debris and identify any potential issues.

- Apply protective coatings or corrosion inhibitors to prevent rust and extend the operational lifespan.

- Store drill pipes in a controlled environment, protecting them from moisture, extreme temperatures, and chemical exposure.

6. Application Cases:

Let's consider two application cases and summarize the relevant parameters in tables:

6.1 Oil Exploration Case:

- Drilling Operation: Offshore Well

- Drill Pipe Grade: API Grade E75

- Drilling Depth: 15,000 ft

- Bit Type: Diamond Bit

| Key Parameters | Values |

| Average ROP | 120 ft/hr |

| Total Drilling Time | 30 days |

| Number of Connections | 75 |

| Total Length of Drill Pipe | 20,000 ft |

6.2 Geothermal Drilling Case:

- Drilling Operation: Geothermal Well

- Drill Pipe Grade: API Grade X95

- Drilling Depth: 5,000 ft

- Bit Type: Tricone Bit

| Key Parameters | Values |

| Average ROP | 80 ft/hr |

| Total Drilling Time | 14 days |

| Number of Connections | 45 |

| Total Length of Drill Pipe | 8,000 ft |

These real application cases provide insights into the performance and parameters associated with standard drill pipes in different drilling scenarios.

Conclusion:

Standard drill pipes play a crucial role in drilling operations across various industries, including oil and gas exploration, geothermal drilling, construction, and mining. Understanding the materials used, key production processes, application scenarios, international inspection standards, maintenance considerations, and real application cases is vital for optimizing drilling performance and ensuring operational safety.

API Grade E75 and API Grade X95 drill pipes, made from high-quality alloy steel, offer reliable strength and durability. Strict adherence to international inspection standards, such as API Spec 7 and ISO 11961, ensures the quality and reliability of standard drill pipes.

By following proper maintenance procedures and taking necessary precautions during use, including regular inspection, adherence to drilling parameters, and appropriate storage, drill pipe longevity and operational efficiency can be maximized.

Real application cases highlight the practical application of standard drill pipes and provide insight into key parameters such as drilling depth, drilling time, number of connections, and total length of drill pipe used. This information helps industry professionals understand the performance and capabilities of drill pipes in real-world scenarios.

Through continuous innovation, adherence to industry standards, and proactive maintenance, standard drill pipes continue to contribute significantly to efficient and successful drilling operations worldwide.

Tags: Drill pipe