-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

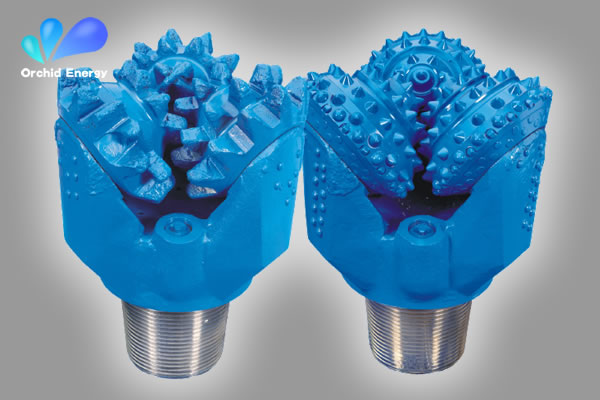

Brief Discussion on Tricone Drill Bit

Introduction:

Tricone drill bits are essential tools in the field of drilling, known for their versatility and efficiency in various drilling operations. In this blog, we will explore the materials used, production processes, different product types and corresponding working principles, application scenarios, international inspection standards, maintenance considerations, and real application cases of tricone drill bits. To enhance comprehension, relevant parameters will be presented in a table format.

1. Materials Used in Tricone Drill Bits:

Tricone drill bits are typically constructed with high-quality materials to withstand the rigors of drilling. Commonly used materials include:

1.1 Tungsten Carbide Inserts (TCI):

TCI inserts are strategically placed on the three cone-shaped structures of the tricone drill bit. These inserts consist of small grains of tungsten carbide embedded in a metallic matrix, providing excellent wear resistance and durability.

1.2 Steel Body:

The body of the tricone drill bit is usually made of high-grade alloy steel, known for its strength, toughness, and resistance to heat and impact. The steel body provides structural integrity to the drill bit.

2. Production Processes:

The production of tricone drill bits involves several key processes, including:

2.1 Material Selection and Preparation:

High-quality tungsten carbide inserts are chosen and prepared for embedding into the bit body. The alloy steel for the bit body is selected based on performance requirements.

2.2 Insert Embedding:

The tungsten carbide inserts are carefully placed in the cavities on the cone structures of the drill bit. These inserts are then securely bonded to the bit body using advanced brazing techniques.

2.3 Heat Treatment:

The entire tricone drill bit is subjected to heat treatment processes to optimize its hardness, toughness, and overall performance.

3. Types of Tricone Drill Bits and Working Principles:

Tricone drill bits come in various types, each designed for specific drilling applications. The different types and their corresponding working principles include:

3.1 Milled Tooth Bits:

Milled tooth bits feature cone structures with milled teeth, which are created by removing metal from the cone body. These bits rely on the penetrating action of the milled teeth to break rocks and create a borehole.

3.2 Tungsten Carbide Insert (TCI) Bits:

TCI bits utilize tungsten carbide inserts strategically placed on the cone structures. These inserts shear and break the formation, enabling the bit to penetrate various rock types effectively.

4. Application Scenarios:

Tricone drill bits are widely used in a range of drilling scenarios, including:

4.1 Oil and Gas Exploration:

Tricone drill bits are commonly employed in oil and gas exploration, enabling efficient drilling through different geological formations, including soft, medium, and hard rock formations.

4.2 Water Well Drilling:

Water well drilling often encounters various formations, and tricone drill bits are well-suited for their versatility in drilling through different soil and rock layers.

5. International Inspection Standards:

International inspection standards ensure the quality and reliability of tricone drill bits. These standards include:

5.1 API Spec 7-1:

API Spec 7-1 provides specifications and inspection requirements for rotary drilling equipment, including tricone drill bits. It covers dimensions, materials, quality control, testing, and marking.

6. Maintenance and Precautions:

Proper maintenance and precautions are essential for maximizing the lifespan and performance of tricone drill bits. Consider the following:

6.1 Precautions During Use:

- Monitor drilling parameters such as weight on bit (WOB), rotary speed, and drilling fluid flow rate to avoid overload or damage to the drill bit.

- Use compatible drilling fluids and control the fluid properties to ensure effective cooling and lubrication.

6.2 Maintenance Methods:

- Regularly inspect the condition of the tricone drill bit, including the wear of tungsten carbide inserts or milled teeth, and replace them when necessary.

- Clean the drill bit after each use to remove debris and prevent corrosion.

7. Real Application Cases:

Let's consider two real-world application cases and summarize the relevant parameters in tables:

7.1 Oil Exploration Case:

- Drilling Operation: Oil Well Exploration

- Tricone Drill Bit Type: Tungsten Carbide Insert (TCI) Bit

- Drilling Formation: Medium-Hard Rock

| Key Parameters | Values |

| Drilling Depth | 5,000 ft |

| Average ROP | 80 ft/hr |

| Total Drilling Time | 10 days |

| Bit Diameter | 8.5 inches |

7.2 Water Well Drilling Case:

- Drilling Operation: Water Well Drilling

- Tricone Drill Bit Type: Milled Tooth Bit

- Drilling Formation: Soft-Medium Rock

| Key Parameters | Values |

| Drilling Depth | 300 ft |

| Average ROP | 40 ft/hr |

| Total Drilling Time | 5 days |

| Bit Diameter | 6 inches |

These real application cases provide insights into the performance and parameters associated with tricone drill bits in different drilling scenarios.

Conclusion:

Tricone drill bits are versatile tools that play a crucial role in drilling operations. Understanding the materials, production processes, different types and working principles, application scenarios, international inspection standards, maintenance practices, and real application cases of tricone drill bits is essential for professionals in the drilling industry. By applying this knowledge, efficiency, reliability, and successful drilling outcomes can be achieved in various formations and drilling projects.

Tags: Tricone Drill Bit