-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

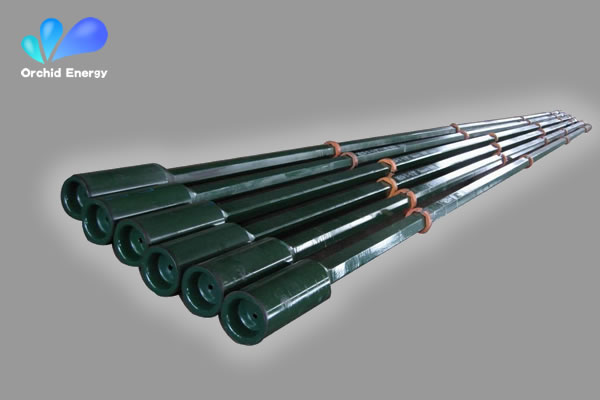

A Comprehensive Guide to Square Kelly and Hexagonal Kelly

Introduction:

In the drilling industry, the Square Kelly and Hexagonal Kelly are vital components used in the rotary table assembly. Both play a crucial role in transmitting rotary motion from the rotary table to the drill string. This blog aims to provide an in-depth understanding of these two product types, including their materials, production processes, working principles, application scenarios, international product inspection standards, real application cases, precautions during use, and maintenance methods.

| Parameters | Square Kelly | Hexagonal Kelly |

|---|---|---|

| Material | High-grade alloy steel | High-grade alloy steel |

| Production Process | Forging and heat treatment | Forging and heat treatment |

| Product Types | Standard, wavy, square fluted | Standard, wavy, hex fluted |

| Working Principle | Transmits rotary motion | Transmits rotary motion |

| Application Scenarios | Oil drilling operations | Oil drilling operations |

| International Product Inspection Standards | API Spec 7-1 | API Spec 7-1 |

| Application Cases | Offshore rig operations | Onshore rig operations |

| Precautions during Use | Regular inspection and maintenance | Regular inspection and maintenance |

| Maintenance Methods | Lubrication, cleaning, and storage | Lubrication, cleaning, and storage |

1. Materials and Production Processes:

Both Square Kelly and Hexagonal Kelly are manufactured using high-grade alloy steel. The production process involves forging and subsequent heat treatment to ensure strength, durability, and resistance to extreme drilling conditions.

2. Product Types and Working Principle:

- Square Kelly: Square Kellies come in standard, wavy, and square fluted variations. They have a square cross-section, allowing for effective torque transmission from the rotary table to the drill string. Square fluting enhances grip and stability during drilling operations.

- Hexagonal Kelly: Hexagonal Kellies, on the other hand, feature a hexagonal cross-section. Like the Square Kelly, Hexagonal Kelly also comes in various types, including standard, wavy, and hex fluted. The hex design improves the overall torque transmission efficiency in the drilling process.

3. Application Scenarios:

Both Square Kelly and Hexagonal Kelly find application in oil drilling operations. They are utilized in both offshore and onshore drilling rigs to ensure efficient transmission of rotational force and torque from the rotary table to the drill string.

4. International Product Inspection Standards:

Square Kelly and Hexagonal Kelly conform to the industry-standard API Specification 7-1, ensuring compliance with quality, performance, and safety standards. These specifications dictate rigorous inspections during the manufacturing process to guarantee reliability and durability.

5. Application Cases:

Square Kelly and Hexagonal Kelly have been extensively employed in various drilling projects worldwide, ranging from offshore rigs in the North Sea to onshore operations in the Middle East. These Kellys have proven their reliability and performance even under demanding drilling conditions.

6. Precautions during Use:

Regular inspection and maintenance are essential to ensure the optimal performance and longevity of Square Kelly and Hexagonal Kelly. This involves monitoring wear and tear, checking for deformities or cracks, and maintaining proper lubrication at all times. Adhering to safety guidelines during operation is crucial to prevent accidents or equipment failures.

7. Maintenance Methods:

Routine maintenance includes periodic cleaning, lubrication of threaded connections, and proper storage in a controlled environment. It is also essential to follow manufacturer guidelines and recommendations for specific maintenance procedures.

Conclusion:

Square Kelly and Hexagonal Kelly are indispensable components in the drilling industry, driving the efficient transmission of rotational force from the rotary table to the drill string. Understanding their materials, production processes, various product types, working principles, applications, inspection standards, real-world cases, precautions, and maintenance methods can equip professionals with the knowledge necessary to ensure optimal performance and safety in drilling operations.

Tags: Square Kelly | Hexagonal Kelly