-

ꁸ Top

-

ꂅ +86 159 1059 4147

-

ꀥ WhatsApp

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

-

HOME

-

ABOUT

-

PRODUCTS

- DRILLING TOOLS

- DRILLING MOTORS

- STABILIZERS

- DRILL COLLARS

- DRILLING JARS

- HYDRAULIC AGITATOR

- ANTI STICK-SLIP TOOL

- MULTIPLE ACTIVATION BYPASS VALVE

- DRILL PIPES

- NON-ROTATING PROTECTOR

- X-OVER & SUBS

- DRILL BITS

- MICRO REAMER

- FISHING TOOLS

- RELEASING SPEAR

- RELEASING AND CIRCULATING OVERSHOT

- REVERSE CIRCULATION JUNK BASKET

- JUNK SUB

- FISHING MAGNET

- SAFETY JOINT

- TAPER TAP

- DIE COLLAR

- IMPRESSION BLOCK

- DITCH MAGNET

- MILLING SHOES

- WASHOVER PIPE

- IBOPs

- KELLY VALVE

- FLOAT VALVE

- FULL OPENING SAFETY VALVE

- TOP DRIVE IBOP

- INSIDE BOP

- DROP-IN CHECK VALVE

- WELLBORE CLEANING TOOLS

- CASING SCRAPER

- NON-ROTARY CASING SCRAPER

- CASING BRUSH

- CUTTING BED IMPELLER

- STRING MAGNET

- ROTARY CASING GUIDER

- CASING CUTTER

- SECTION MILL

- WELLHEAD TOOLS

- ELEVATORS

- ELEVATOR LINKS

- POWER TONGS

- MANUAL TONGS

- SLIPS

- SPIDERS

- SPINNING WRENCH

- BUSHINGS

- DRILLING EQUIPMENTS

- MUD PUMP

- VALVE SEAT AND BODY

- PISTON

- CYLINDER LINER

- HYDRAULIC BUCKING UNIT

- JAR TESTER

- FRAC PUMP VALVE RUBBER

- FRAC PUMP VALVE BODY

- FRAC PUMP VALVE SEAT

- FRAC PUMP PLUNGER PACKING

-

PRESS

-

CONTACT

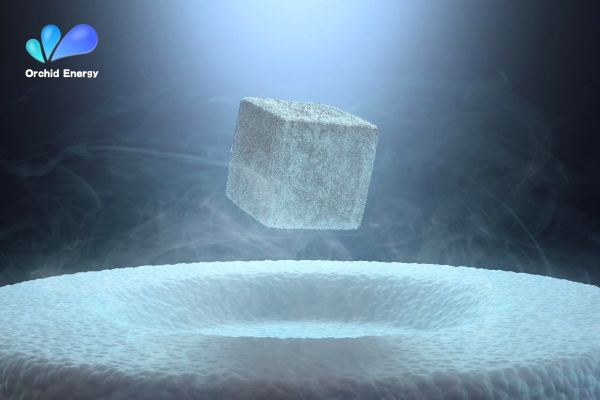

The Impact of Room Temperature Superconductivity on the Drilling Industry from the Perspective of LK-99

Introduction:

The drilling industry has long been at the forefront of technological advancements, constantly searching for ways to improve efficiency, increase productivity, and reduce costs. The emergence of room temperature superconductivity could be a game-changer for this sector, unlocking a host of possibilities and revolutionizing the way drilling operations are conducted. In this blog, we will explore in detail the potential changes that could be brought to the drilling industry if room temperature superconductivity becomes a reality.

Picture Credit: KNEWS

1. Enhanced Drilling Equipment:

One of the most significant impacts of room temperature superconductivity in the drilling industry would be the development of highly advanced drilling equipment. Superconducting materials exhibit zero electrical resistance, leading to the creation of more efficient motors, turbines, and generators. These superconducting devices would require less energy input and generate minimal heat, resulting in reduced downtime and increased durability.

2. Improved Efficiency and Cost Savings:

The adoption of room temperature superconductivity could revolutionize drilling processes by improving overall efficiency. Superconducting transmission cables would substantially reduce energy losses during power transmission, resulting in significant cost savings. As a result, drilling companies would be able to achieve higher operational output with reduced energy consumption, resulting in a more sustainable and cost-effective drilling industry.

3. Greater Depth and Precision:

With the development of room temperature superconductivity, drilling depths that were previously considered unattainable could become a reality. The enhanced efficiency of superconducting drilling equipment would enable drill bits to penetrate deeper into the Earth's crust, unlocking previously untapped resources. Moreover, the increased precision resulting from the stability and accuracy of superconducting materials would minimize the risk of drilling errors, reducing environmental impact and optimizing resource extraction.

4. Advanced Magnetic Resonance Imaging (MRI) for Geological Analysis:

Incorporating room temperature superconductivity into drilling operations would facilitate the use of advanced magnetic resonance imaging (MRI) techniques for comprehensive geological analysis. Superconducting magnets would allow for highly accurate and detailed imaging of subsurface formations, providing valuable insights into the availability and quality of resources. This enhanced geological understanding would enable drilling companies to make informed decisions regarding drilling locations, reducing the likelihood of unsuccessful operations and optimizing resource utilization.

5. Increased Safety Measures:

Safety is a paramount concern in the drilling industry. The implementation of room temperature superconductivity could introduce several safety improvements. The decreased power consumption of superconducting equipment would reduce the risk of overheating and potential accidents. Additionally, the stability and reliability of superconducting materials would contribute to more secure drilling operations, minimizing the likelihood of operational failures and associated risks.

Conclusion:

While the realization of room temperature superconductivity is still a topic of ongoing research, the potential impact on the drilling industry is immense. From enhanced drilling equipment to cost savings, deeper drilling capabilities, advanced geological analysis, and increased safety measures, room temperature superconductivity could transform the way drilling operations are carried out. As the technology progresses and further breakthroughs occur, it is essential for the drilling industry to embrace these changes to drive innovation and shape a more sustainable future for resource extraction.

Tags: Drilling Motors | Stabilizers